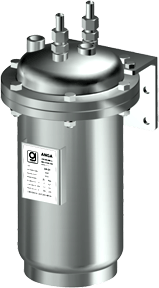

ANGA's accredited testing laboratory performs metrological measurements primarily for the demanding aerospace market (Aviomechanika), but also for industrial customers from other branches, e.g. in scope of calibration and reverse engineering. The advantages of cooperation with our laboratory are: reliability (PCA accreditation), quality and precision (we have highly qualified staff and state-of-the-art measurement equipment, which ensures the accuracy of the results).

Testing laboratory

Accredited laboratory

ANGA Testing Laboratory is accredited by the Polish Centre for Accreditation (PCA), Accreditation No. AB 701.

The Testing Laboratory offers measurement services (metrologhttps://www.anga.com.pl/wp-content/uploads/2024/08/ANGA-LABORATORIUM-BADAWCZE-AB701-20ical) falling within the scope of:

- spatial measurements of products geometry with the use of the Coordinate Measuring Machine (CMM),

- spatial measurements of products and comparing them with mathematical models of surfaces from CAD systems,

- spatial measurements of products and generating mathematical models of surface,

- measurements of roughness, corrugation, original profile, surface shape, radius and angle parameters.

Testing Methods

| Tested objects group of objects | Tested features and testing methods |

|---|---|

|

|

|

|

|

|

|

Testing laboratory

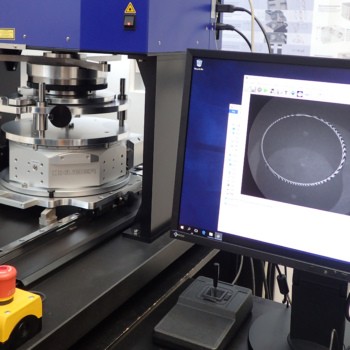

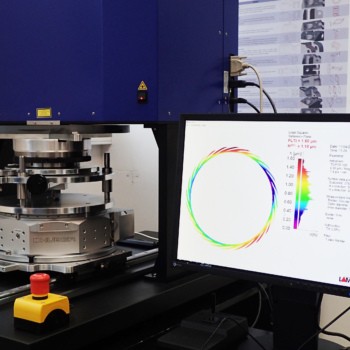

Interferometric measurements of flatness (non-accredited)

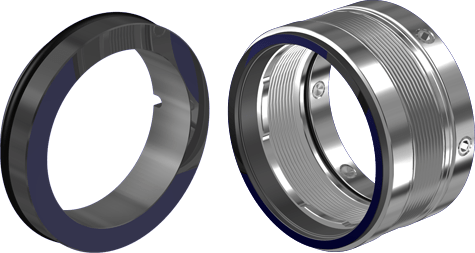

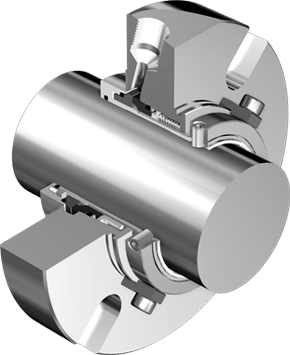

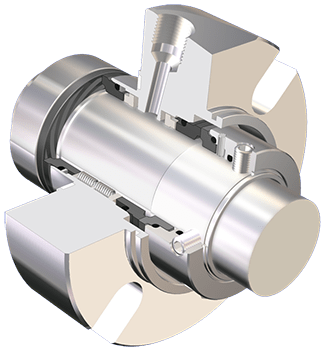

With the use of interferometer analysis, flatness of different types of surface can be measured. This method is particularly preferred when measuring flatness of the surfaces of precise machine parts, including face mechanical seals. With the touchless optic technology, an analysis of the whole part surface, regardless of its size or complexity, can be conducted in a few seconds. Among other measurements, interferometry is distinguished mainly by precision, it eliminates interpretation ambiguities of interference spectrum and measures precisely even very small changes in surface height.

Advantages of interferometric analysis:

- The measurement is insensitive to vibrations and air turbulences;

- Measurement results are quantitative and repeatable, there is no place for subjective interpretation;

- Graphic presentation of measurement result allows the surface profile to be viewed;

- Lack of contact between part and datum surface, thereby an actual non-contact measurement;

- Measurement of parts of diameter up to 100 mm in one measurement without shifting the part.

TESTED ITEMS

Products made of metal, plastics, ceramics, glass and other materials; surfaces can be ground, lapped or polished.

TESTED ITEMS RANGE

Rings up to 400 mm OD with the method of combining obtained images, up to 80 mm wide and weighing up to 10 kg.

FEATURES ANALYSED

Flatness, line profile, surface topography.

TEST RESULTS

Results can be presented in diverse graphic versions: in false colours, as linear cross-sections, radial development, flatness relief imaging, in a spreadsheet, as 3D polygon mesh.

How can we help?

Contact form

Contact us

ANGA Uszczelnienia Mechaniczne Sp. z o. o.

(ANGA Mechanical Seals LLC)

ul. Wyzwolenia 550

43-340 Kozy

Poland

Our experts will answer questions

You are welcome from Monday to Friday

from 7:00 a.m. to 3:00 p.m.