Seal and pump regeneration services have many advantages. Cost savings - regeneration is usually cheaper than buying new ones, e.g. seals, and extending the life of machines allows for their later purchase. Ecology - Regeneration helps reduce the amount of waste and the consumption of natural resources. Technology - regeneration is an opportunity to increase the reliability of e.g. seals by implementing modifications. Time - the regeneration process is faster than waiting for the delivery of new ones, e.g. seals, which minimizes production downtime.

Services

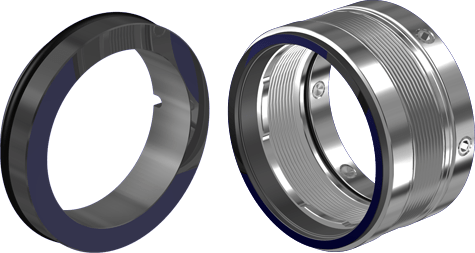

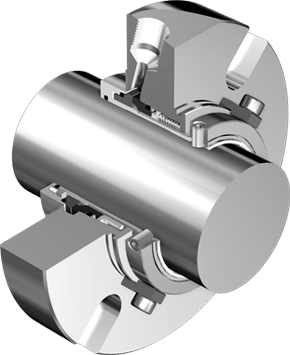

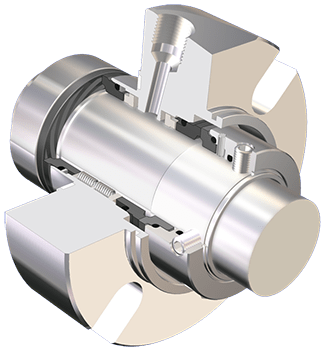

Seal service

We offer a full service of:

- mechanical seals manufactured by ANGA, with the possibility of servicing at the customer’s plant,

- mechanical seals by other manufacturers,

- sealing heads,

- dividing heads,

- slide bearings of silicon carbides (SiC) and other materials,

- labyrinth sealing systems.

The benefits of cooperation with ANGA service are as follows:

- over 40 years experience in the manufacture and regeneration of mechanical seals,

- qualified and experienced expert staff,

- short completion dates (lead-times),

- own production of sealing rings from carbon composites, sintered silicon carbide and other materials,

- regenerated sealing units are tested in a specialist testing station,

- reports from compact (cartridge) seal tests,

- specialist equipment resources for manufacturing and regeneration of mechanical seals.

Services

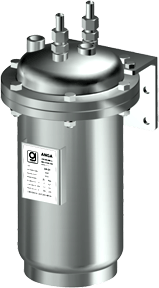

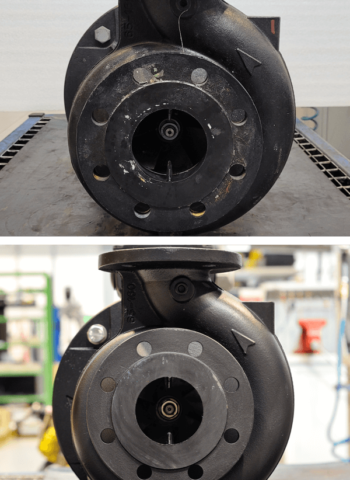

Pump repairs

Using over 40 years of experience in the pump sector, its modern technical resources and a team of experienced specialists, ANGA offers its customers:

- repairs of impeller and displacement pumps (peripheral, worm, screw, plunger, lobar),

- pump repairs of the majority of known Polish and foreign manufacturers,

- repairs of pumps operating in difficult working conditions (submersible and deep-well pumps, for aggressive media, operating in high temperatures),

- adaptation of pumps from braided packing to mechanical seals.

Thanks to cooperation with ANGA, our customers receive a comprehensive service including:

- technical inspection of pumps,

- repair documentation, repair history, test reports available for the customer,

- dynamic testing of impeller pumps at a specialist station,

- replacement or regeneration of mechanical seals in pumps,

- replacement of various types of bearings,

- regeneration of electric motors,

- painting and cleaning of pumps and motors,

- dynamic balancing of pump impellers,

- alignment of pump units with laser devices.

Services

Consultancy and training

For many years ANGA has been sharing with its customers its knowledge and experience in seal and pump engineering.

We organize training and provide technical consultancy concerning the selection, assembly and operation of mechanical seals. This is above all technical training for direct operation employees (maintenance function), repair workshops and engineering and technical staff.

ANGA also offers individual training thematically suited to your needs and requirements. Training can be held at the ANGA head office, in the customer’s head office or in an agreed training and conference centre.

Services

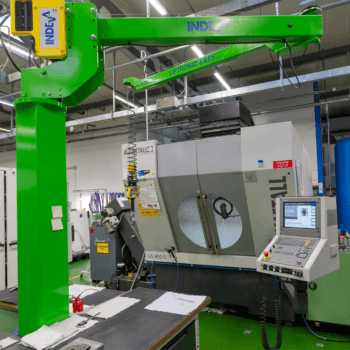

Precision machining

In the process of mechanical seal manufacturing ANGA and its subsidiaries Aviomechanika and Certech, have gained experience in the precision machining of parts made of various materials: stainless steels, aluminium alloys, nickel alloys, magnesium and titanium alloys as well as almost unworkable materials such as silicon carbide, tungsten carbide and Al2O3 ceramics.

We specialize in the machining of parts of machines and equipment using modern numerically controlled machines (CNC). We perform:

- turning,

- 4- and 5- axial milling,

- grinding,

- polishing,

- lapping,

- thermal and thermal and chemical treatment.

Among the advantages of cooperating with ANGA in regard to mechanical processing are the following:

- quality assurance system based on ISO 9001 and AS9100 standards,

- parts made according to the customer’s documentation (drawings, 3D models),

- short time of new production launch,

- flexibility and short completion dates (lead-times),

- control of products by the accredited Testing Laboratory (metrological measurements).

Services

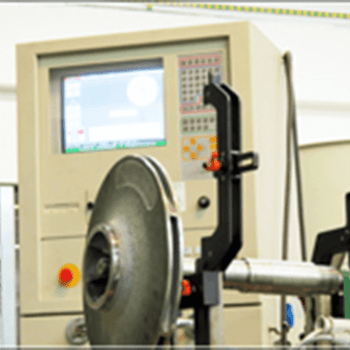

Balancing, alignment

Balancing

We perform dynamical balancing of:

- pump impellers of weight up to 50 kg and diameter up to 600 mm,

- shafts of weight up to 50 kg, neck diameters from 6 mm to 40 mm, and lengths up to 1000 mm.

We ensure balancing accuracy of up to G 0.4 and we issue a Balancing Report on Customer’s request.

Alignment

We offer laser alignment of pumping engines, to be done at the customer’s plant during service trips or in ANGA head office. We issue Alignment Reports on customer’s request.

How can we help?

Contact form

Contact us

ANGA Uszczelnienia Mechaniczne Sp. z o. o.

(ANGA Mechanical Seals LLC)

ul. Wyzwolenia 550

43-340 Kozy

Poland

Our experts will answer questions

You are welcome from Monday to Friday

from 7:00 a.m. to 3:00 p.m.