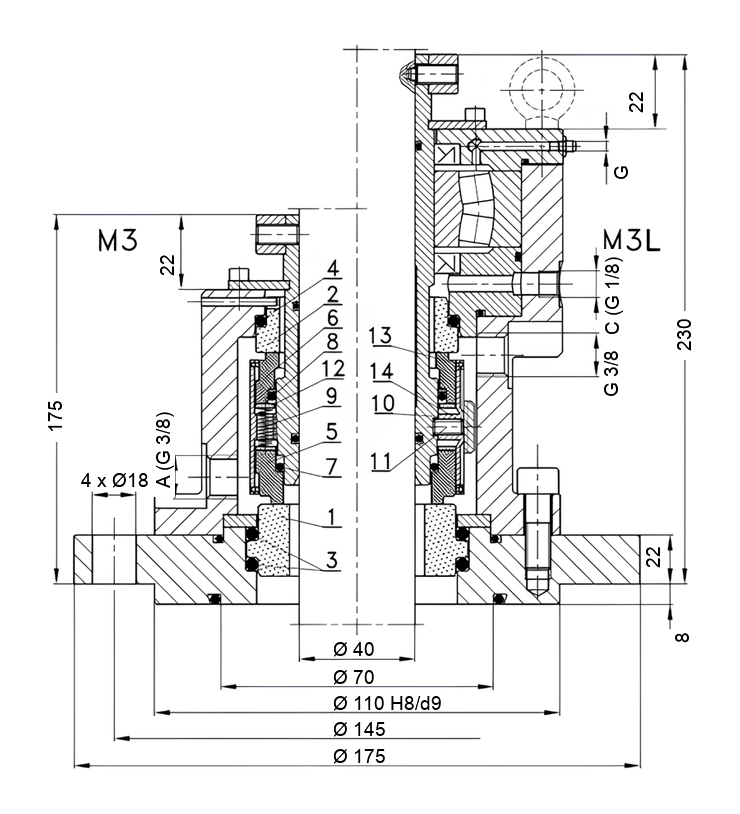

The dimensions of the 40M3 / M3L seal are shown above. Seals M3 / M3L in other sizes are shown in the configurator and catalogue card, available at the top of the page.

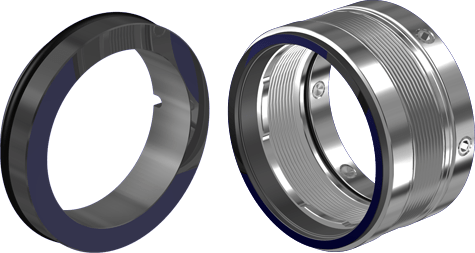

Legend

- 1. Stationary ring

- 2. Stationary ring

- 3. O-ring

- 4. O-ring

- 5. Rotating ring

- 6. Rotating ring

- 7. O-ring

- 8. O-ring

- 9. Springs

- 10. Housing

- 11. Clamping screws

- 12. Thrust ring

- 13. Expanding ring

- 14. Sleeve with a thread

- 15. O-ring

General characteristics

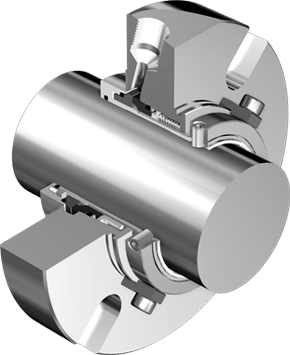

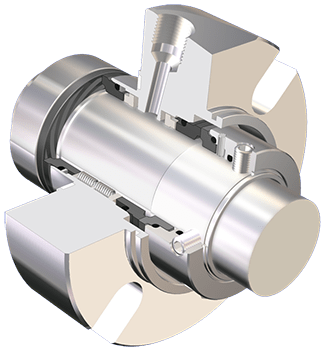

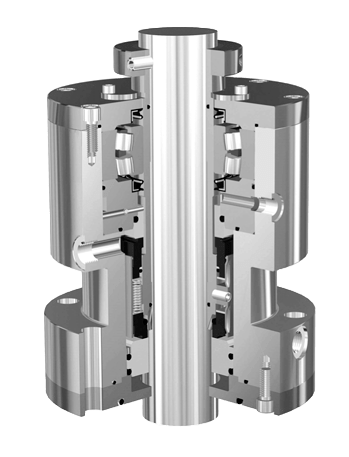

Double mixer seal, balanced, independent from the direction of rotation, multi-spring.

Two options: M3 – without bearing, M3L – with bearing.

Range of sizes available

- Shaft diameter: d = 40 ... 120 mm

Operating parameters

- Pressure: < 2.5 MPa

- Temperature: < 200 °C

- Velocity: < 4.0 m/s

Applications

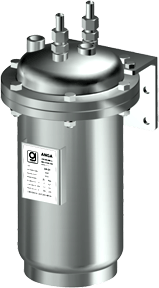

The M3 and M3L seals are designed for sealing shafts of mixers and reactors, in which chemically aggressive and environmentally hazardous products are processed. The seals are adapted for operating with low-pressure installations of barrier or flushing-cooling fluids. M3L seals perform the function of a shaft bearing unit.

Available options

![]()

ATEX versions are available.

Available with materials compliant with FDA and EC 1935/2004.

Materials

- Rotating ring: A, B, Q

- Stationary ring : Q, U2, V

- Secondary flexible seals: E, K, M, V

- Spring (springs): G, M

- Other metal parts: G, M

- Rotating ring (atmosphere side): A, B, Q

- Stationary ring (atm. side): Q, U2, V

- Secondary flexible seals (atm. side): E, K, M, V