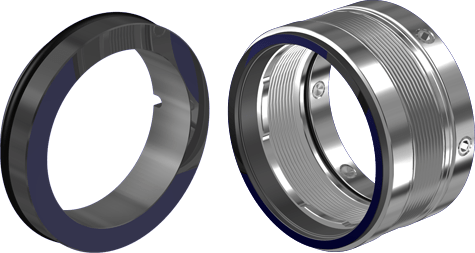

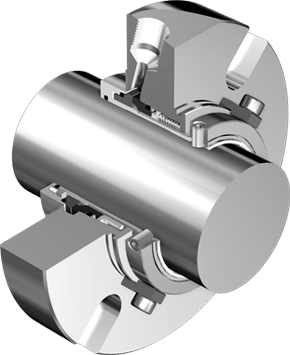

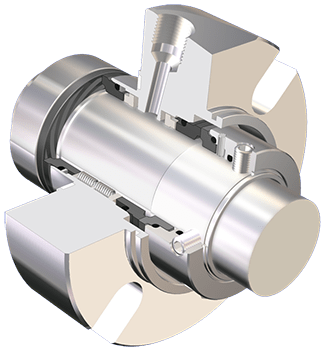

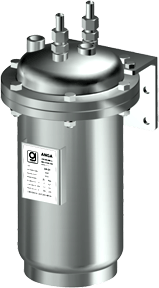

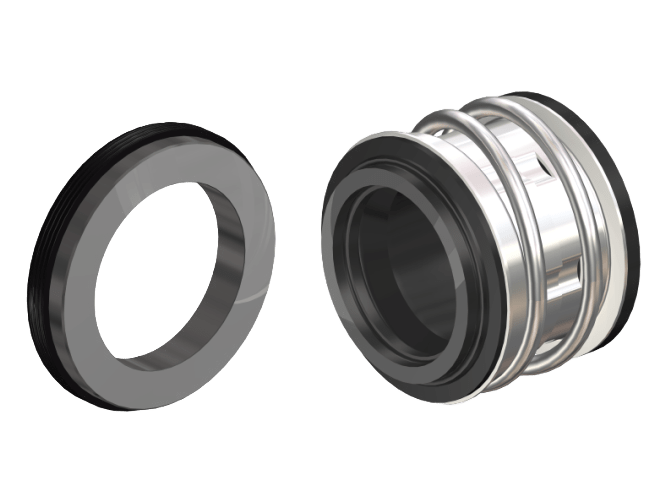

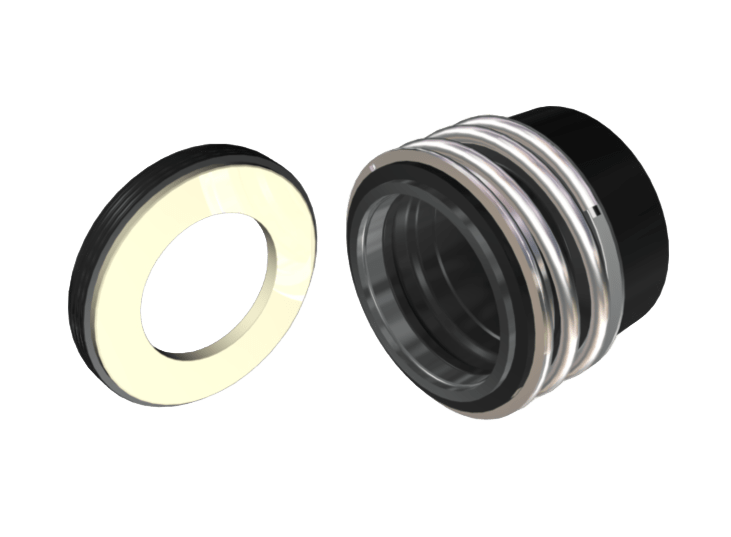

A1G

It is a general purpose mechanical seal for operation with water, oils, fuels and liquids containing small amounts of abrasive substances, used in impeller pumps and other equipment with rotating shafts. A1G is a version of the A1 with extended bellows, adapted for special installation conditions.