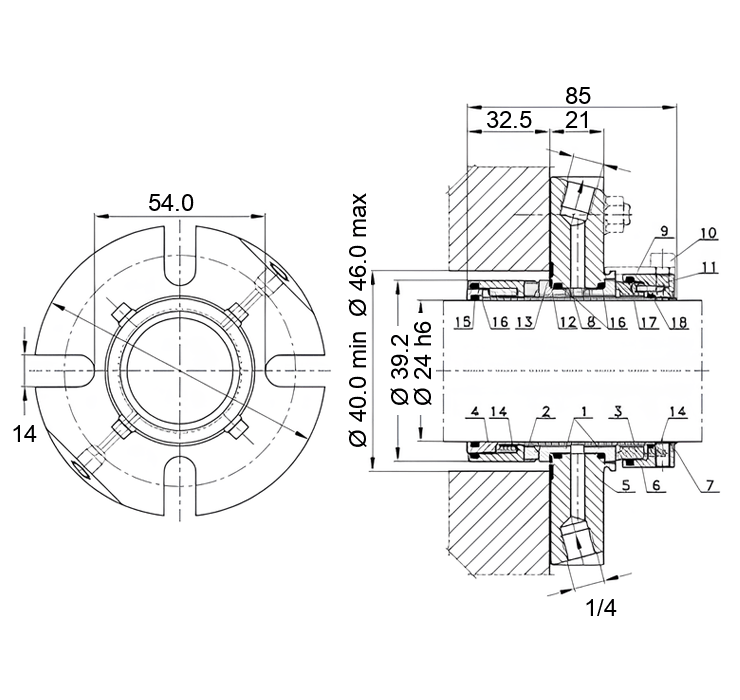

The dimensions of the 24USP seal are shown above. Seals USP in other sizes are shown in the configurator and catalogue card, available at the top of the page.

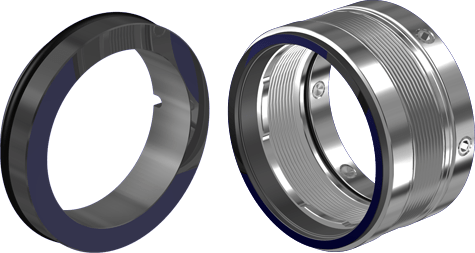

Legend

- 1. Stationary ring

- 2. Rotating ring

- 3. Rotating ring

- 4. Sleeve

- 5. Cover

- 6. Clamping ring

- 7. Expanding ring

- 8. Pin

- 9. Distance plate

- 10. Socket head screw

- 11. Set screw

- 12. Thrust ring

- 13. Flat gasket

- 14. Spring

- 15. O-ring

- 16. O-ring

- 17. O-ring

- 18. O-ring

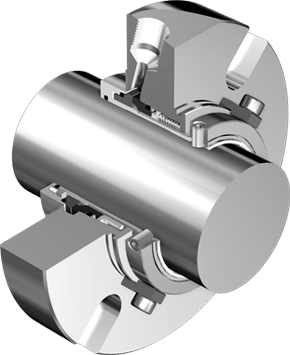

General characteristics

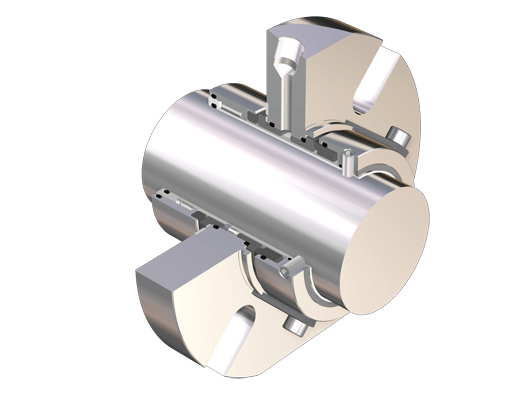

Double seal, compact (cartridge) design, balanced, independent from the direction of rotation, multi-spring.

Range of sizes available

- Shaft diameter: d = 24 ... 125 mm

Operating parameters

- Pressure: < 2,0 MPa

- Temperature: < 120 °C

- Velocity: < 12,5 m/s

Applications

The USP is a mechanical seal used for viscid media containing abrasive particles.

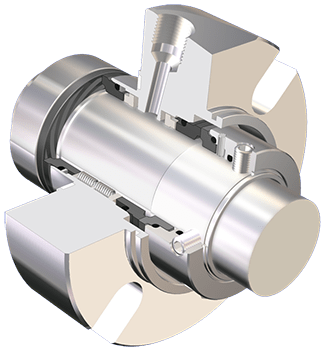

The USP seal requires the following liquid installations:

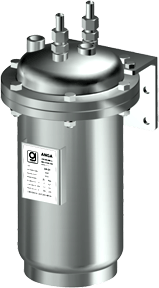

– buffer liquid (API Plan 52 ) or

– barrier liquid (API Plan 53), note: max. pressure of barrier liquid: 1.6 MPa, max. overpressure: 0.6 MPa.

Available options

![]()

ATEX versions are available.

Available with materials compliant with FDA and EC 1935/2004.

Materials

- Rotating ring: A, B, Q, U, U1, U2

- Stationary ring : Q, U, U1, U2

- Secondary flexible seals: E, K, M, V

- Spring (springs): M

- Other metal parts: G, M

- Rotating ring (atmosphere side): A, B, Q, U, U1, U2

- Stationary ring (atm. side): Q, U, U1, U2

- Secondary flexible seals (atm. side): E, K, M, V