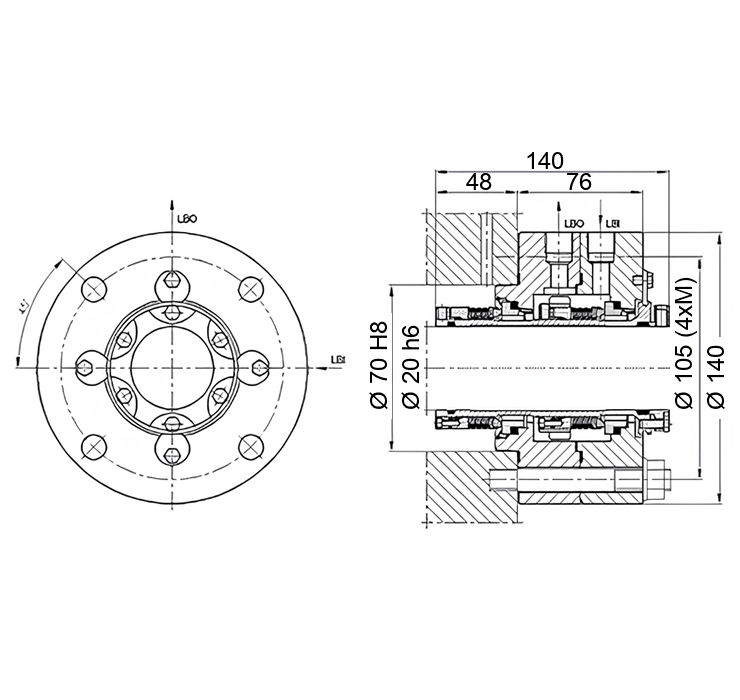

The dimensions of the 20EPD seal are shown above. Seals EPD in other sizes are shown in the configurator and catalogue card, available at the top of the page.

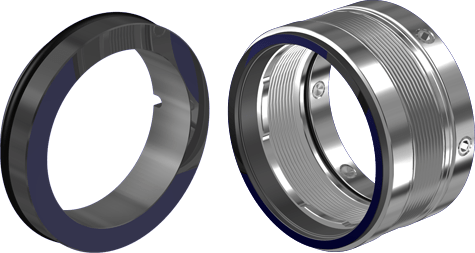

Legend

- 1. Stationary ring

- 2. Sealing ring

- 3. Bellows outer unit

- 4. Sealing ring

- 5. Socket head screw

- 6. Bellows inner unit

- 7. Sealing ring

- 8. Screw

- 9. Sleeve

- 10. Sealing ring

- 11. Clamping ring

- 12. Thrust ring

- 13. Set screw

- 14. Screw

- 15. Set screw

- 16. Seal cover 1

- 17. Seal cover 2

- 18. Seal cover 3

- 19. Sealing ring

- 20. Socket head screw

- 21. Socket head screw

- 22. Cover insert

- 23. Socket head screw

- 24. Retaining plate

- 25. Socket head screw

- 26. Pumping ring

- 27. Distance plate

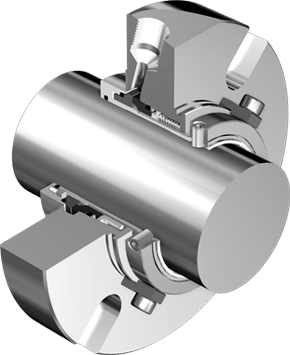

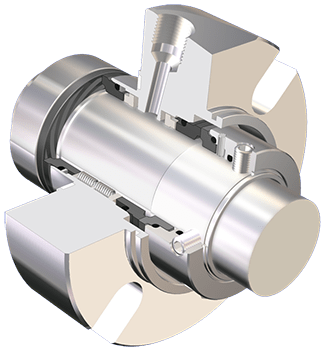

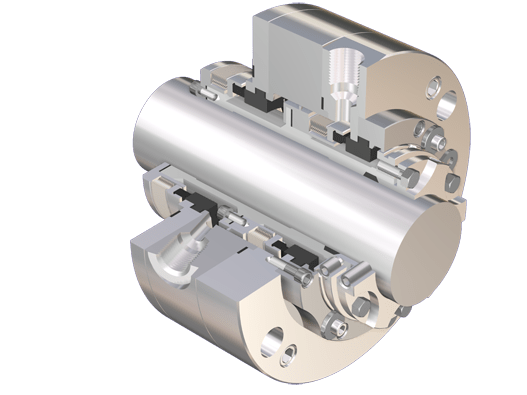

General characteristics

Double seal with metal bellows, compact (cartridge) design, balanced, dependent from the direction of rotation, plasticized graphite secondary seals. The seal acc. to EN ISO 21049 (API 682): type C, category 2 or 3, arrangement 2 or 3, configuration 2CW-CW or 3CW-FB.

Range of sizes available

- Shaft diameter: d = 20 ... 90 mm

Operating parameters

- Pressure: < 1.2MPa

- Temperature: -50 < t < 400°C

- Velocity: v < 25 m/s

Applications

The EPD is a double mechanical seal designed to work with hot hydrocarbons in the petroleum refining processes.

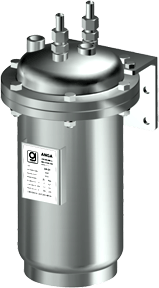

The EPD seal requires the application of auxiliary installations according to API 682 Plan 52 or Plan 53. EPD seals are designed in accordance with the guidelines of EN ISO 21049 (API 682).

Available options

![]()

Materials

- Rotating ring: A, Q, U

- Stationary ring : Q, U

- Secondary flexible seals: G

- Bellows: G, M

- Other metal parts: G, M

- Rotating ring (atmosphere side): A, Q, U

- Stationary ring (atm. side): Q, U

- Secondary flexible seals (atm. side): G