The dimensions of the 40BPD seal are shown above. Seals BPD in other sizes are shown in the configurator and catalogue card, available at the top of the page.

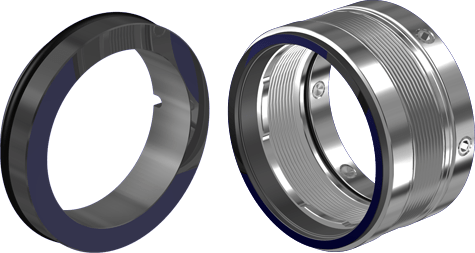

Legend

- 1. Rotating ring BP

- 2. O-ring

- 3. Stationary ring BP

- 4. O-ring

- 5. Sleeve

- 6. O-ring

- 7. O-ring

- 8. O-ring

- 9. Rotating ring BP

- 10. O-ring

- 11. Stationary ring BP

- 12. O-ring

- 13. O-ring

- 14. Cover I

- 15. Cover insert

- 16. O-ring

- 17. O-ring

- 18. Expanding ring BP

- 19. Spring

- 20. Cover II

- 21. Sleeve

- 22. O-ring

- 23. Fixing ring BP

- 24. Set screw

- 25. Distance plate

- 26. Socket head screw

General characteristics

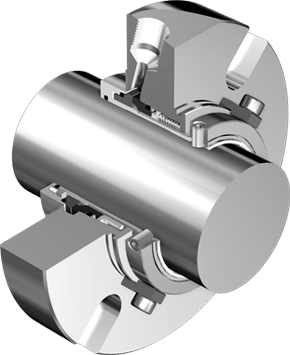

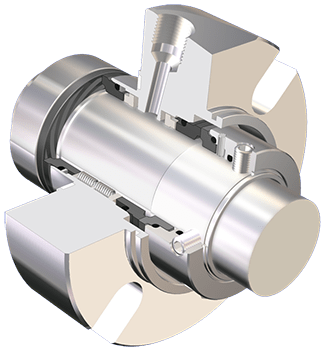

Double seal, cartridge design, balanced, direction of rotation-dependent, multi-spring. BPD seal requires application of buffer or barrier liquid installation. The seal acc. to EN ISO 21049 (API 682): type A, category 2 or 3, arrangement 2 or 3, configuration 2CW-CW or 3CW-FB.

Range of sizes available

- Shaft diameter: d = 40 ... 110 mm

Operating parameters

- Pressure: < 3.5 ... 2.2 MPa

- Temperature: < -40 ... 250 °C

- Velocity: < 15 m/s

Applications

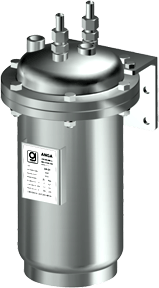

The BPD is a general purpose mechanical seal designed especially for pump installations for liquefied hydrocarbons of low density, and high pressures, occurring in refineries, in petrochemical and chemical industries. This mechanical seal is designed for clean media (without mechanical inclusions and abrasives): some organic acids, higher hydrocarbons, propane-butane, ethanol, acetone, cumene, unsaturated aliphatic hydrocarbons (olefins CnH2n). BPD seals eliminate harmful emissions of process medium to the environment by using a tandem seal arrangement according to API 682 type 2 with cooling-separating liquid installation and atmospheric tank.

– cartridge construction, easy assembly and disassembly

– resistance against the deformation of sealing rings due to cooling

– forced circulation of quench (cooling) fluid acc. to API 682 plan 54

– low friction due to the optimal form of main sealing rings

– possibility to monitor the seals operation by quench fluid control

– pumps doesn’t stop working in case of the failure of the main seal

Available options

![]()

Materials

- Rotating ring: Q, U

- Stationary ring : A, B, Q, U

- Secondary flexible seals: E, K, V

- Spring (springs): M

- Other metal parts: G, M

- Rotating ring (atmosphere side): Q, U

- Stationary ring (atm. side): A, B, Q, U

- Secondary flexible seals (atm. side): E, K, V