The dimensions of the 22GF seal are shown above. Seals GF in other sizes are shown in the configurator and catalogue card, available at the top of the page.

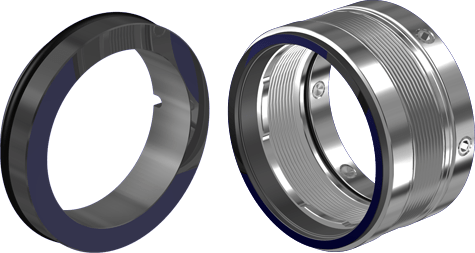

Legend

- 1. Stationary ring

- 2. O-ring

- 3. Springs

- 4. Rotating ring

- 5. O-ring

- 6. Pin

- 7. Securing ring

- 8. Sleeve

- 9. O-ring

- 10. Locating pin

- 11. Locating pin

- 12. Cover insert

- 13. Cover

- 14. Flat gasket

- 15. O-ring

- 16. Clamping ring

- 17. Set screw

- 18. Securing ring

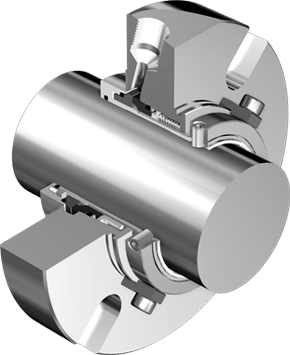

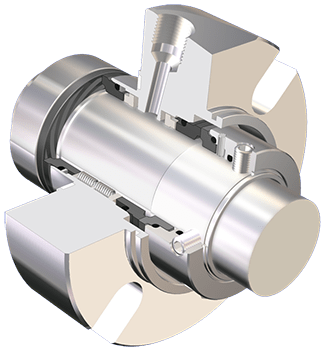

General characteristics

Double seal in “face to face” installation, compact (cartridge) design, balanced, dependent on the direction of shaft rotation (GFR – right, GFL – left), multi-spring. Requires powering with barrier gas.

Range of sizes available

- Shaft diameter: d = 22 ... 75 mm

Operating parameters

- Pressure: < 1.2 MPa

- Temperature: < 200 °C

- Velocity: > 1 m/s

Applications

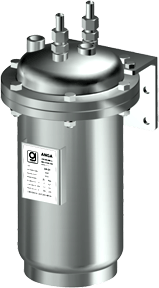

The GF is a mechanical seal recommended for applications where particular product purity must be ensured and where friction heat causes its changes. It is designed to work with toxic, carcinogenic, explosive media, for process gases, etc., in chemical, petrochemical, pharmaceutical, metallurgical industries and coking plants.

Features:

– very long lifetime and long MTBF (mean time between failures),

– possible operation in media, which do not form a lubricating film,

– no emission of harmful media into the atmosphere, ensures complete leak tightness of the pump (also in the event of a barrier gas pressure failure occurs, the seal continues to operate in the contact mode).

Available options

![]()

Materials

- Rotating ring: Q, U

- Stationary ring : A, B

- Secondary flexible seals: E, K, V

- Spring (springs): M

- Other metal parts: G, M

- Rotating ring (atmosphere side): Q, U

- Stationary ring (atm. side): A, B

- Secondary flexible seals (atm. side): E, K, V