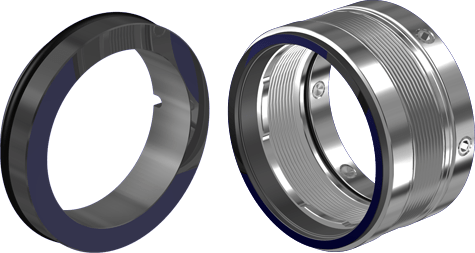

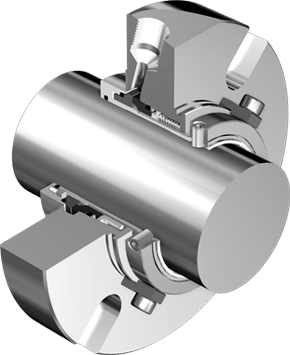

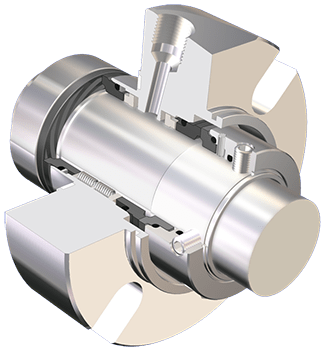

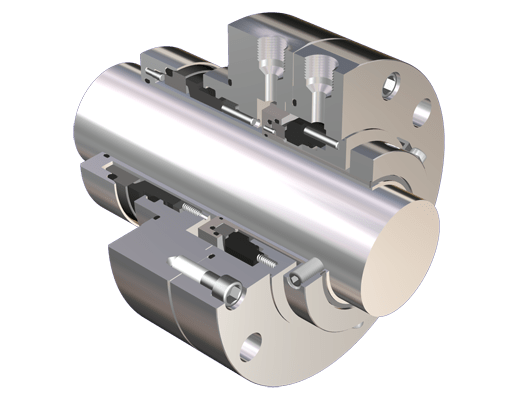

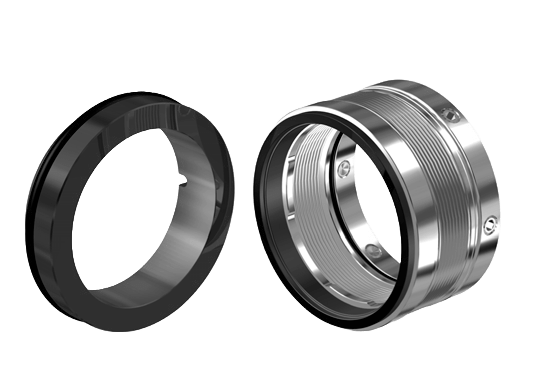

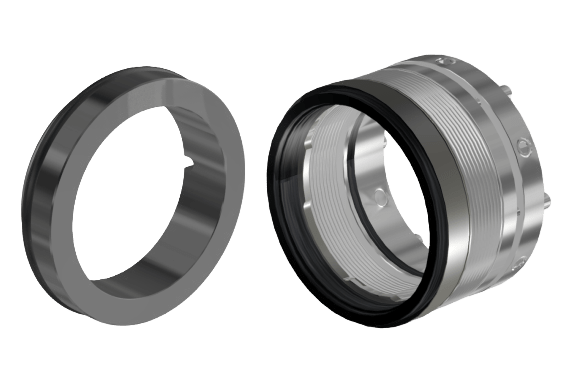

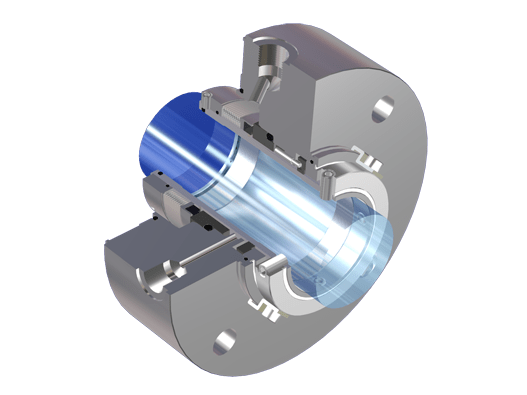

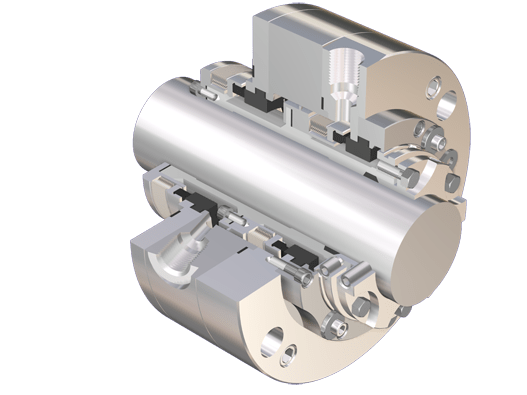

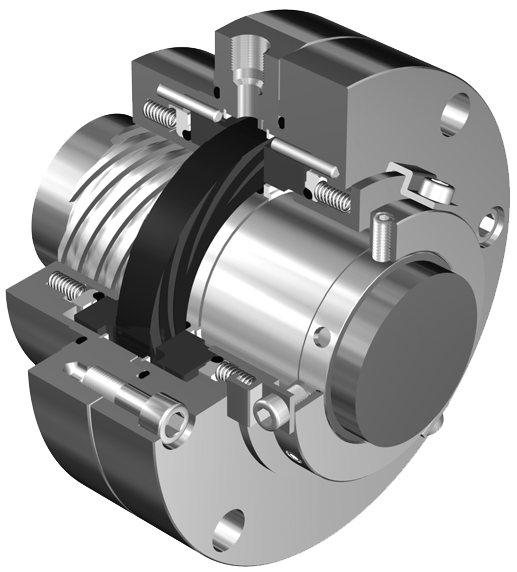

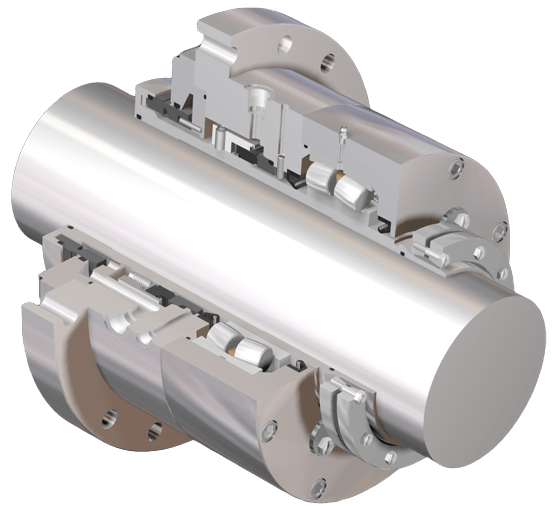

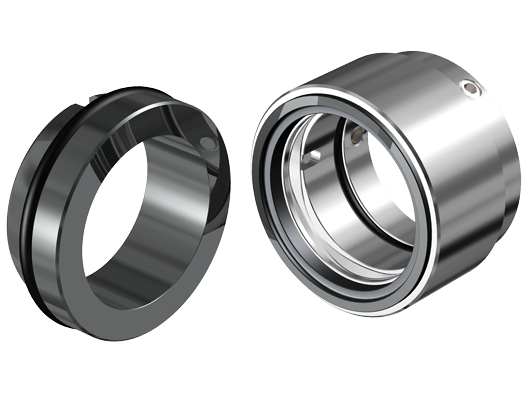

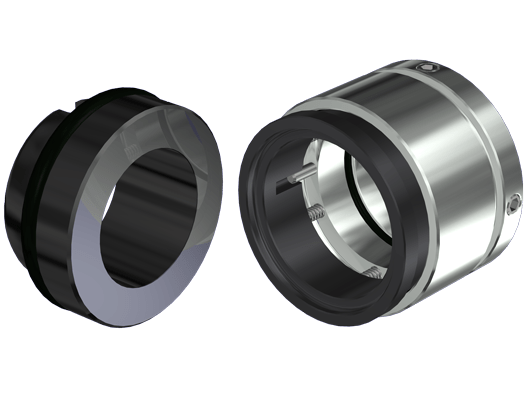

BU

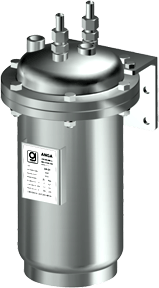

The BU is a single mechanical seal used for media contaminated with particulate solids, especially, e.g., crude oil and polluted hydrocarbons. BU seal requires auxiliary installations acc. to API 682 (EN ISO 21049), Plan: 11/61, 11/62, 12/61, 12/62, 13/61, 13/62.