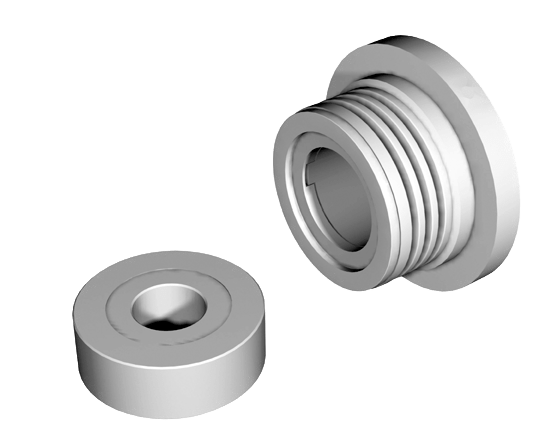

A12

It is a mechanical seal intended for operating with extremely aggressive chemicals which do not contain abrasive particles. Metal components of the A12 seal do not touch the sealed medium.

ul. Wyzwolenia 550

43-340 Kozy

Poland

You are welcome from Monday to Friday

from 7:00 a.m. to 3:00 p.m.