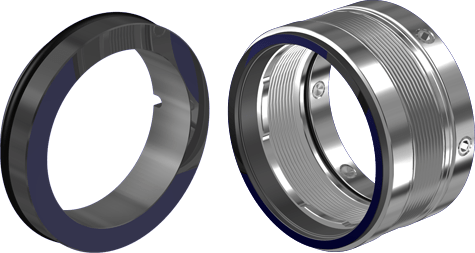

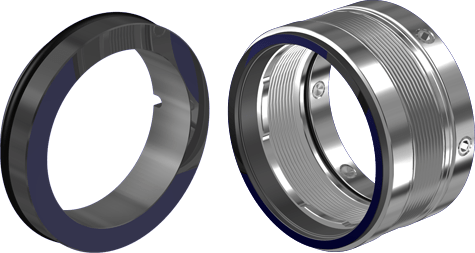

Component seals consist of two main elements: a rotating (dynamic) part, bolted to the machine shaft, and a fixed (stationary) part assembled in the cover or housing of the machine. Compared to cartridge seals, component seals are not pre-assembled and their assembly requires experience and the necessary measurements to set the correct working length of the mechanical seal.