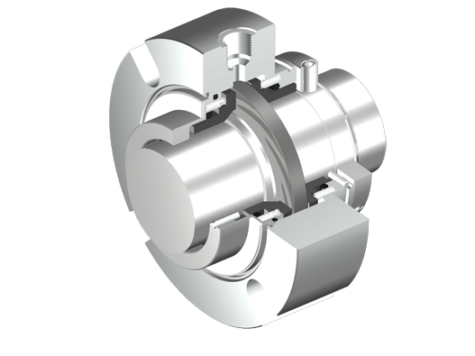

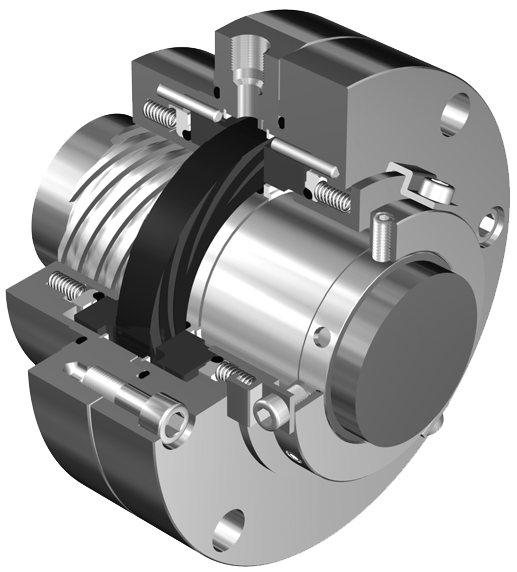

GF

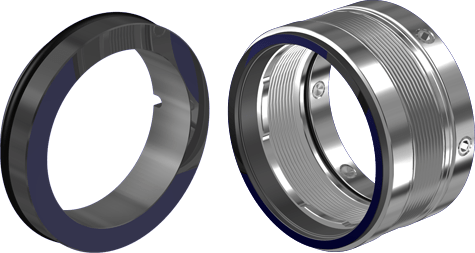

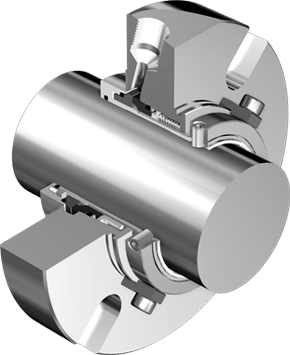

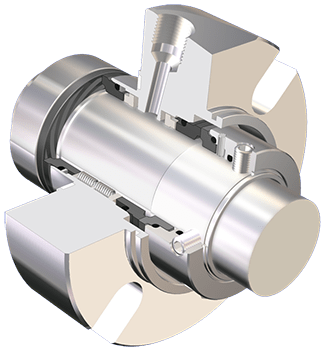

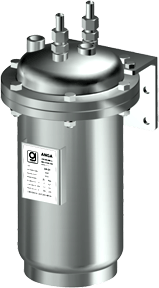

The GF is a mechanical seal recommended for applications where particular product purity must be ensured and where friction heat causes its changes. It is designed to work with toxic, carcinogenic, explosive (with the possibility of self-ignition) media, for process gases, etc., in chemical, petrochemical, pharmaceutical, metallurgical, coking plants and other industries.