BE2

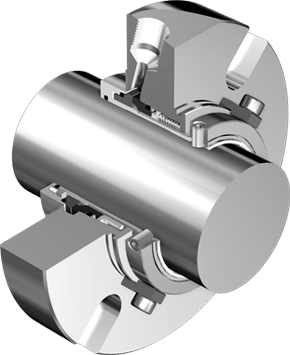

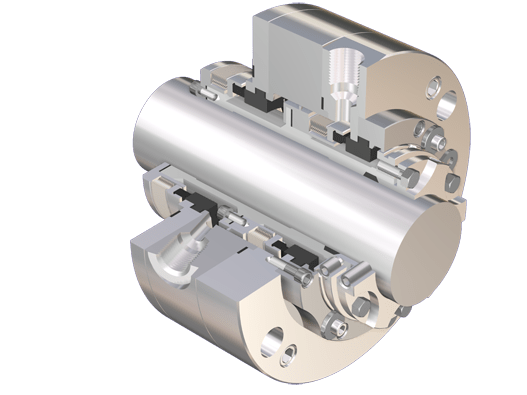

It is a general purpose mechanical seal with a wide range of applications. It is designed to operate with cold and hot water, oils, fuels, not very aggressive chemicals and other liquids contaminated with solid particles.

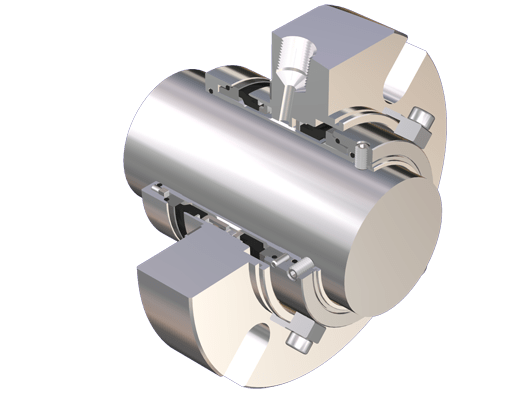

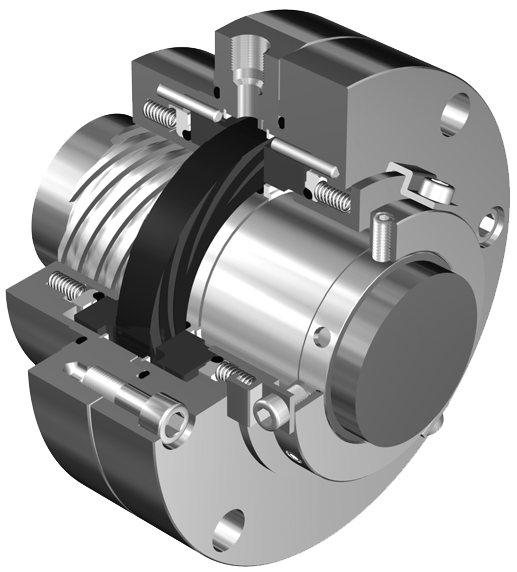

It is a general purpose mechanical seal with a wide range of applications. It is designed to work with media containing abrasive particles (e.g., ash, ores, cement, sludge and suspended matter) and chemicals harmful to the environment. BED seal requires installation of a system of buffer liquid (acc. to API Plan 52, 55) or barrier liquid (API Plan 53a, 53b, 53c, 54). Maximum pressure of barrier liquid: 2.0 MPa.

The BEQ is a general purpose mechanical seal with a wide range of applications. It is designed to operate with cold and hot water, oils, fuels, not very aggressive chemicals and other liquids contaminated with solid particles. Compact construction enables direct application in chambers with braided packing. BEQ seal can be connected to an outer quenching system acc. to API Plan 11/61 or 32/61.

It is a general purpose mechanical seal designed especially for pump installations for liquefied hydrocarbons of low density, and high pressures, occurring in refineries, in petrochemical and chemical industries. This mechanical seal is designed for clean media (without mechanical inclusions and abrasives): some organic acids, higher hydrocarbons, propane-butane, ethanol, acetone, cumene, unsaturated aliphatic hydrocarbons (olefins CnH2n).

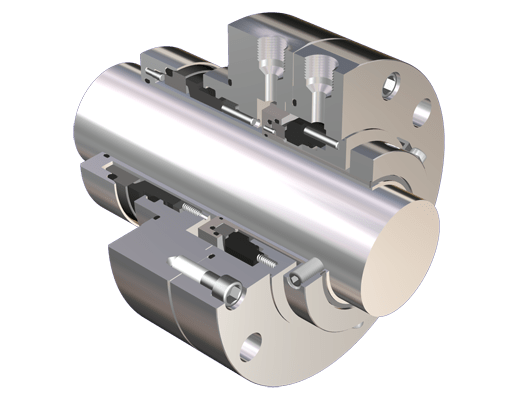

It is a general purpose mechanical seal designed especially for pump installations for liquefied hydrocarbons of low density, and high pressures, occurring in refineries, in petrochemical and chemical industries. This mechanical seal is designed for the following media: propane-butane, ethanol, acetone, cumene, unsaturated aliphatic hydrocarbons (olefins CnH2n) of high purity, without mechanical inclusions and abrasive contamination. BPD seal can also be successfully used for clean chemicals, some organic acids and higher hydrocarbons. BPD seals eliminate harmful emissions of process medium to the environment by using a tandem seal arrangement according to API 682 type 2 with cooling-separating liquid installation and atmospheric tank.

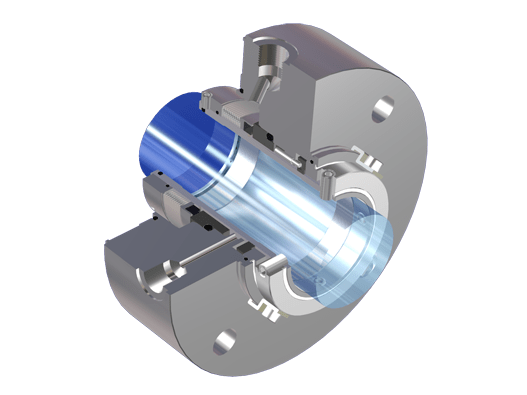

The EP is a seal designed to work with hydrocarbons appearing in the petroleum refining processes. It is designed acc. to the recommendations of ISO 21049 Std. (API 682). EP seal is adapted to operation in the systems acc. to AP 682 standards, configuration: from the process medium side acc. to Plan 11, 12,.13, 23, 31 or 32; whereas from the atmosphere side Plan 61, 62 or 65.

It is a double mechanical seal designed for work with hot hydrocarbons in the petroleum refining processes. The EPD seal requires the application of auxiliary installations according to API 682 Plan 52 or Plan 53. EPD seals are designed in accordance with the guidelines of EN ISO 21049 (API 682).

The GF is a mechanical seal recommended for applications where particular product purity must be ensured and where friction heat causes its changes. It is designed to work with toxic, carcinogenic, explosive (with the possibility of self-ignition) media, for process gases, etc., in chemical, petrochemical, pharmaceutical, metallurgical, coking plants and other industries.

The GK seals are designed mostly for process pumps used in refining and petrochemical industries, in chemical industry and coking plants, and in particular in pump installations with a high level of explosion risks and increased emissions of volatile substances into the environment. The GK seal requires continuous supplying with filtered barrier gas (most commonly nitrogen) of pressure ~ 0.2 MPa higher than the sealed medium pressure.

The M1 and M1L seals are designed for sealing shafts of mixers and reactors, in which non-aggressive and environmentally safe products are processed. The seals are adapted for operating with low-pressure installations of flushing-cooling liquids. M1L seals perform the function of shaft bearing unit.

ul. Wyzwolenia 550

43-340 Kozy

Poland

You are welcome from Monday to Friday

from 7:00 a.m. to 3:00 p.m.