Seals for explosive atmospheres (Ex)

In explosive atmospheres (Ex), it is crucial to ensure that the equipment and its components are not a potential source of ignition. For mechanical seals, particular attention must be paid to the surface temperature. Friction between the sealing ring and mating ring leads to heat generation, resulting in an increase in temperature.

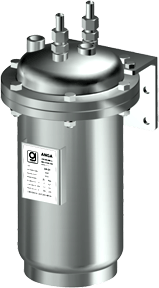

During testing, ANGA verifies that the surface temperature is within the permissible limits specified for the temperature class. Testing under simulated operating conditions helps verify the assumptions and conclusions of the ignition risk analysis, to ensure safe operation of the seal and the machine in which it is installed.

ANGA seals, which are currently available for explosion hazardous areas, are marked ‘Ex’ in the catalogue.

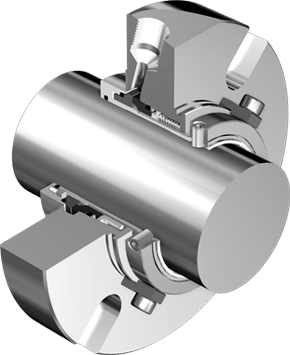

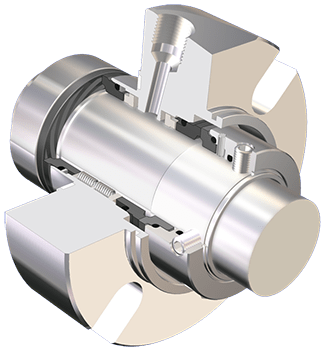

Pictured is the M3L type double mechanical seal, with integrated bearing, during ATEX testing.