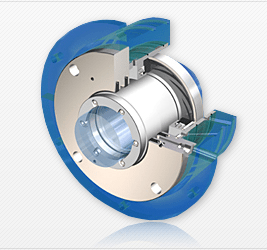

GK GAS LUBRICATED COMPRESSOR SEALS

GK seals are used in various types of flow compressors. They eliminate traditional oil, labyrinth or segment seals.

They are above all used in chemical, refining, petrochemical industries, coking plants, technical or natural gas transportation, etc.

Sealed agents: gases or vapours of explosive and chemically aggressive liquids such as ammonia, methane, ethylene, propane, toluene, acetone, hydrogen chloride, hydrogen sulfide, carbon oxide, etc.

GK seals are excellent for explosion-hazard zones or those polluting the natural environment.

Our GK series seals are indispensable during renovations and extensive repairs of compressors.

ADVANTAGES OF GK SEALS

- contactless operation while maintaining the air-tight sealing of the area sealed with the gas (most often nitrogen),

- reduction of power consumption due to frictionless operation,

- modular design enabling installation in single and double systems,

- made as a compact suitable for direct assembly and disassembly,

- ensure system tightness during stoppage,

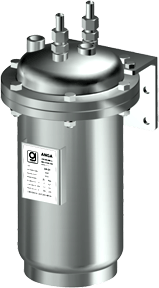

- control and measurement units monitor seal operation in a continual or periodical mode,

- they bring financial savings as a result of the extension of time between overhauls and the reduction of maintenance costs.

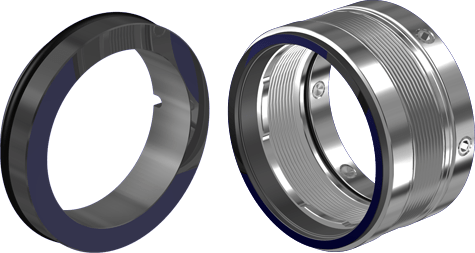

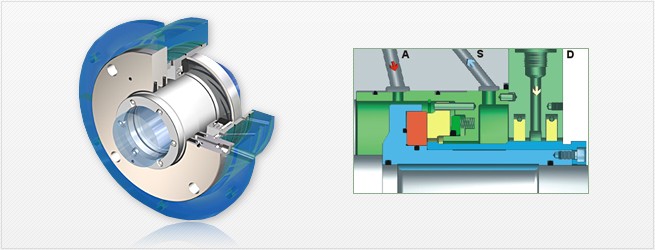

GKP GAS LUBRICATED COMPRESSOR SEAL

Installation in a single system.

Application:

In gas compressors of low responsibility, friendly to the environment and with low operating parameters.

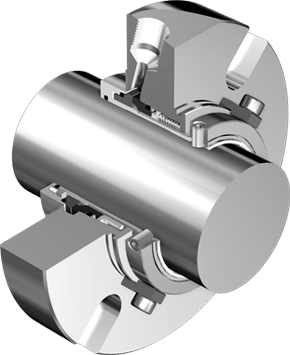

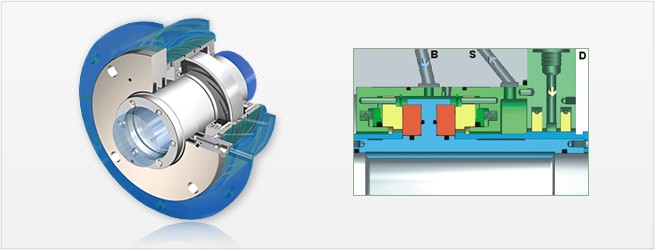

GKF GAS LUBRICATED COMPRESSOR SEAL

Installation in a double face system – “face to face”.

Application:

For gases which are especially chemically aggressive, but of low process pressures, with relatively short installation.

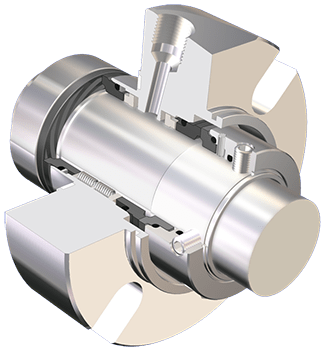

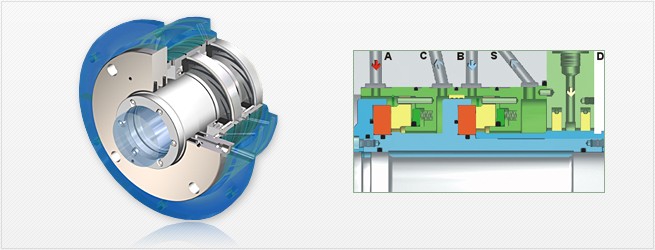

GKT GAS LUBRICATED COMPRESSOR SEAL

Installation in a double string system– “tandem”.

.

Application:

Most popular in case of explosive and toxic process gases.