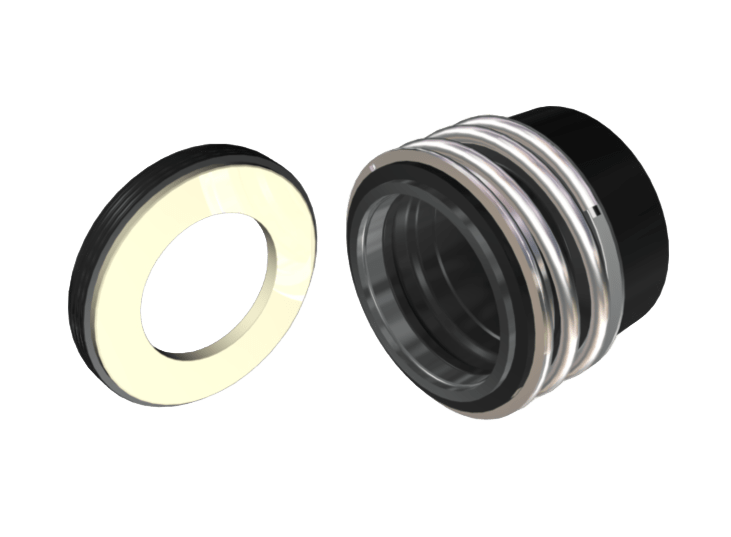

BE2

It is a general purpose mechanical seal with a wide range of applications. It is designed to operate with cold and hot water, oils, fuels, not very aggressive chemicals and other liquids contaminated with solid particles.

Russian and English languages

German and English languages

It is a general purpose mechanical seal with a wide range of applications. It is designed to operate with cold and hot water, oils, fuels, not very aggressive chemicals and other liquids contaminated with solid particles.

It is a general purpose mechanical seal with a wide range of applications. It is designed to operate with cold and hot water, oils, fuels, not very aggressive chemicals and other liquids containing small amounts of abrasives. The A3 seal with a central spring is dependent on the direction of the shaft rotation.

It is a general purpose mechanical seal for operation with water, oils, fuels and liquids containing small amounts of abrasive substances, used in impeller pumps and other equipment with rotating shafts. A1G is a version of the A1 with extended bellows, adapted for special installation conditions.

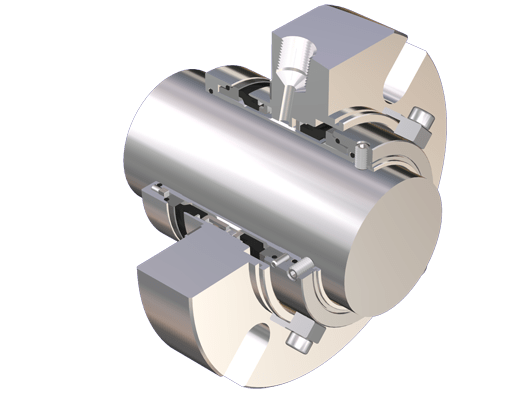

It is a general purpose mechanical seal with a wide range of applications. It is designed to work with media containing abrasive particles (e.g., ash, ores, cement, sludge and suspended matter) and chemicals harmful to the environment. BED seal requires installation of a system of buffer liquid (acc. to API Plan 52, 55) or barrier liquid (API Plan 53a, 53b, 53c, 54). Maximum pressure of barrier liquid: 2.0 MPa.

ul. Wyzwolenia 550

43-340 Kozy

Poland

You are welcome from Monday to Friday

from 7:00 a.m. to 3:00 p.m.